The formula for scaling the number of die per wafer

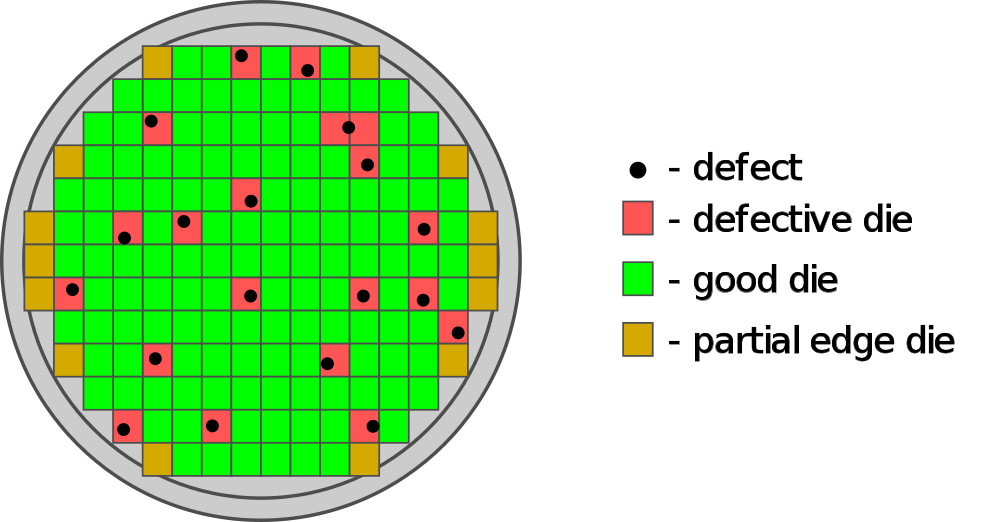

Determination of die per wafer or DPW is completely easy. This process is associated with geometry. It correlates with the circle square formula, namely the Pi.

The total number of dice obtained from the silicon wafer can be arranged in the form of a square. This dice figure will occupy the space of the circle. So, for the calculation, one need to square the circle, and then determine the size of the wafer. For the first problem, it is appropriate to use the mathematical number Pi. It’s 3,14159.

At the same time, the dimensions of die and wafer are already available. However, linear notches, so-called scribes, between squares, as well as gaps along the edges of the wafer, constitute a small difficulty. These areas are obviously not used, which makes it difficult to calculate. In this regard, it is recommended to use the results obtained using the Die Per Wafer technique to evaluate, and not to calculate.

Free Die Per Wafer Calculator

Scribing or notching is part of the process in micro system electronics. The essence of this process is to apply hairlines to the surface of the wafer. At the same time, they must be made in two directions and be perpendicular to each other. For this, special tools are used: diamond cutter, laser or wire. As a result of this method, the wafer can be broken first into strips and then into dice.

Also, in microelectronic production, it is planned to use an added area for tests (PCM structure). So the small wafer size will also be consumed. The intended tracks or hairlines, the clearance from the frontier line of the pattern to the wafer’s, as well as the proportion of the test architecture modify from one functional node to another, from one microelectronic production to another. Experts strongly advise obtaining DPW quantities precisely from the production process in microelectronics, since all the accurate data and characteristics necessary to derive ultimate parameters are received in this way.

Free Silicon’s DPW technology

This die per wafer calculator is quite accessible and works by applying such equation:

“d” is wafer diameter in mm.

“S” is die grade in square mm.